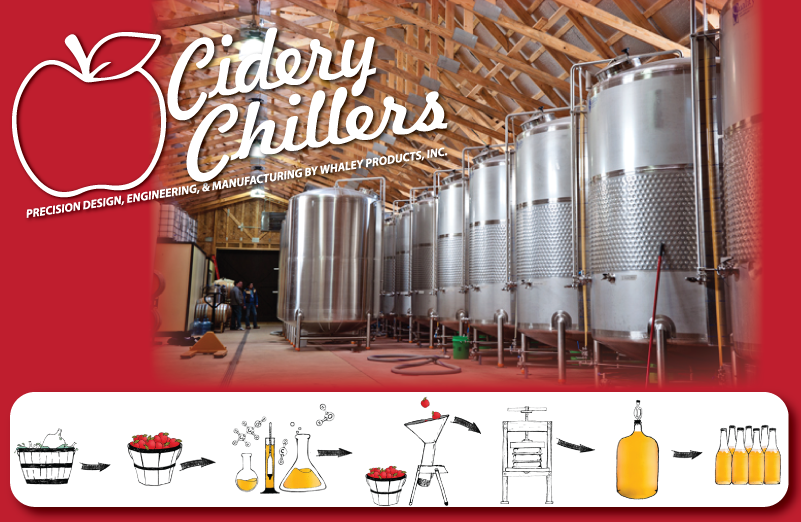

It takes 11-14 pounds of apples to make a single gallon of hard cider. The production process varies slightly from brewer to brewer. The general process for making hard cider is outlined below.

Harvest

Apples in the United States are harvested in the fall. They are picked by hand or with tree shakers. They are put into bins that hold about a half ton of apples. A tractor takes them to the processing plant from the field. They are stored outside in the bins for about a week to let the fruit soften and increase the amount of sugar present in the juice.

Washing

Once the apples have “mellowed” in the bins they need to be washed. This removes dirt, leaves, twigs, and chemical residues from the apples. Any rotten or molding fruit is removed from the batch. The use of clean and intact apples is essential to the flavor of the cider.

Scratting & Pressing

Scratting also known as grinding, involves pulverizing the whole apples into an applesauce like paste. This allows for the maximum amount of juice to be released. Once the pulp has been finely ground it is placed into steel holding barrels for freezing to be used in winter months or sent on to the presses. The Presses squeeze the juice from the solid apple pulp. The pulp is placed in a form lined with cheese cloth. The cloth corners are tightly folded over and the form is removed. This process is repeated 10 to 12 times stacking the cheese cloth forms on top of one another. This stack is then moved to the press where 30,000 lbs. of pressure from a hydraulic pump is applied. The cider is collected and pumped into a cooling tank. In the cooling tank the cider is kept at 33⁰F to inhibit microbial contamination.

Fermentation

Fermentation of cider occurs in two ways. The cider will start to naturally ferment after several weeks of refrigeration. However, most manufacturers add ingredients to the cider to produce a more controllable flavor. These ingredients vary across the industry and include sulfur dioxide, yeast, sugar, honey, ammonium sulfate, and thiamine. Yeast converts the sugars present in the cider to alcohol, then lactic acid bacteria converts the malic acid into carbon dioxide. Complete fermentation of the cider takes a month or more to occur. The cider is kept in sealed bulk tanks and then syphoned out to be bottled.

Blending

Typically a brewery blends cider made from different types of apples together to achieve a full bodied flavor. There are four variations of apple juice aromatic, astringent, acid-tart, and neutral. A typical blend consists of 50% neutral, 20% tart, 20% aromatic, and 10% astringent. At this stage of the production process citric, malic, or tartaric acids can also be added. This adds to the flavor of the finished cider and helps inhibit microbial contamination.

Bottling

Bottling most commonly occurs after fermentation takes place. The cider is pumped from the bulk tank through a filter and into a filling machine. Sterile bottles are loaded onto a conveyor where they are filled, capped and labeled. They are then boxed and moved onto pallets and left to cool at just above freezing until they are shipped off to consumers. Some manufacturers allow the cider to ferment in the bottles. This leaves a sediment layer of left over fermenting yeast at the bottom of the bottle. This is why the more desirable bottling method filters the cider as it is pumped from the bulk tanks to the filling machine.